01

Hydro Electric Power Plant

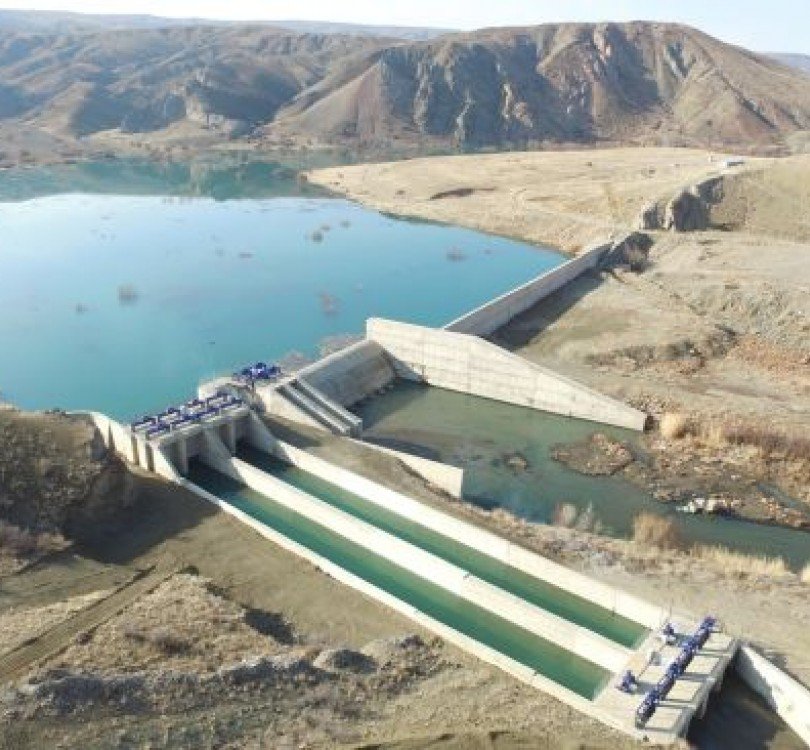

The basis of sustainable development is clean energy. In this context, investments and efforts to utilise the renewable energy source potential of our country have been continuing to increase in recent years. As Anadolu Iplik Group, we have initiated Sofular Hydroelectric Power Plant Project to provide added value to the renewable energy production of our country and to thereby transform this potential of our country to the benefit of society. Our Sofular Hydroelectric Power Plant Project is located in the province of Malatya, district of Kuluncak, the neighbourhood of Sofular, on the Balıklı Tohma stream. Our predicted annual energy production is predicted to be 15 Million KWH on average, with the Energy Market Regulation Authority granting the Electricity Production License (3.083 MWm/2.911 MWe) with the license number EÜ/1391-7-1010 on 29.11.2007 to a company of our group, Şekerpınar Electricity Production Ltd. Company. Moreover, the Ministry of Environment and Urbanisation gave an Environmental Impact Assessment Positive Report on 22.05.2018 to our project.

In our project, water used in our turbines for the production of electricity will be released back to the stream bed in the same quantity; therefore, the water used in the turbines in our plant will return to the stream bed in the same quantity and without any changes to its quality. Thus, it will produce the electrical energy our country needs without harming nature and the environment in any way. The energy to be produced in the plant will be transferred to the countrywide energy network (Interconnected Network) in full. In this way, our plant will help meet the energy need of our country which rises in parallel with the rise in population and the growth of the industry, thereby constituting an important step towards reducing the external dependence of Turkey in the field of energy.

02

Trigeneration

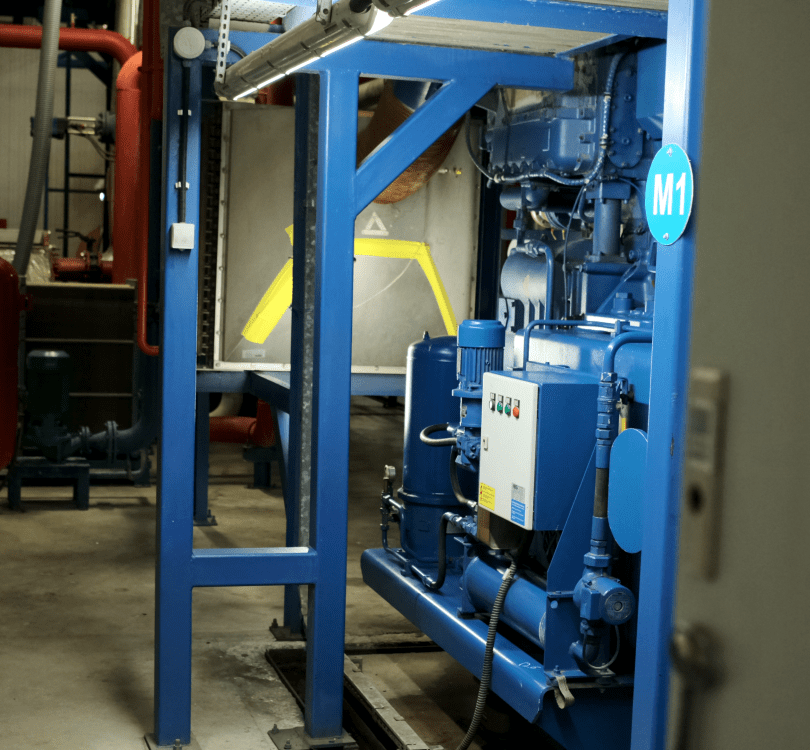

Trigeneration system refers to the system that can produce cooling energy in addition to electricity and heat energy. The Trigeneration system in our enterprise consists of the Gas engine, Electricity Generator, Absorption Chiller and Waste Heat Boiler. The mechanical movement in the Gas engine's shaft is transformed to electrical energy through the Alternator, the heat in the engine jacket water is transformed into cooling energy by Absorption Chiller and the exhaust heat is transformed into the steam energy that we use in the processes of our enterprise through the waste heat Boiler.

Advantages

- While producing the same amount of energy, it is environment-friendly as it emits less CO2.

- Thanks to production of energy at the consumption point, transmission and distribution losses are less.

- It ensures uninterrupted and quality electricity production. The enterprise's processes are thus immune to blackouts.

- It ensures high energy and fuel savings.

Our factory contains two 4,3MW Gas Engines, two 10 bar steam boilers with a capacity of 2.6 tonnes each and a 1061 kW Chiller. Thanks to these advantages obtained from Waste Heat by the trigeneration system, an average of 237 tonnes of CO2 emission in 2020 and a total of 380 tonnes of CO2 emission in December 2020 were prevented. Trigeneration facilities lower the energy costs and make significant contributions to energy efficiency. Trigeneration system has been preferred due to its advantages such as using the energy efficiently in an environment of growing competition, lowering the external dependence of electrical energy and its growing green actions thanks to low stack gas.

03

Dope-Dyed

In the traditional method of dyeing (boiler - hank - bobbin dyeing) which is largely employed by many firms, an extreme amount of clean underground water is used and therefore water, which is our valuable natural resource, is being depleted. Moreover, this water is polluted by colourants and auxiliary chemicals that are used, harming the environment, nature and all living creatures in varying degrees by mixing into streams and rivers. Aware of this negativity and respecting nature, Anadolu Yarn performs the yarn dyeing process without using water in any way, using instead the modern dyeing method of dyeing with coloured pigment (Dope-dyed dyeing). In this method, two solid materials are mixed in certain quantities, melted with heat and then drawn as yarn, thereby producing dyed yarn.

04

Recycled Product

Certified Recycled Product (GRS)

With the increase in the world population and the changes in our consumption habits, our natural resources are being depleted with each passing day. Therefore, it is vital to reduce material consumption and use natural resources efficiently by recycling recyclable Polyamide (Nylon) waste. Our firm aim to use mostly recycled raw materials in our textile products and offer our products without compromising their quality. Within this scope, having put the necessary efforts and investments and having obtained the authorised documents and certificates, our establishment is able to produce all products in our product range to comply with GRS and RCS in desired percentages and offer our customers certified products.05

Recycling Facility

As a reflection of our responsibility for the environment and nature, our firm has made the necessary investment to recycle the waste material that necessarily emerges out of certain phases of production. In the commissioned facility, waste material is put through various phases such as breaking, melting, cooling, making into fibre and cutting, and then transformed back into granules. Through this way, a sustainable source is created and fed back to the production system.